Mechanical Belt Fasteners

Our mechanical belt fasteners provide a robust and secure solution for joining conveyor belts. These fasteners ensure a reliable and durable connection, enhancing the longevity and performance of conveyor systems. Trust Davis Industrial, the best conveyor component company in Florida to supply your organization with the highest-quality mechanical belt fasteners to improve the operation of your conveyor systems.

Selecting the Right Mechanical Belt Fastener

Choosing the correct mechanical belt fastening system is a crucial step when it comes to splicing a belt. We carry a large stock of a comprehensive selection of mechanical belt fasteners in both our Miami and Tampa warehouses. No matter the type or amount of belt fastener you need, we got you covered.

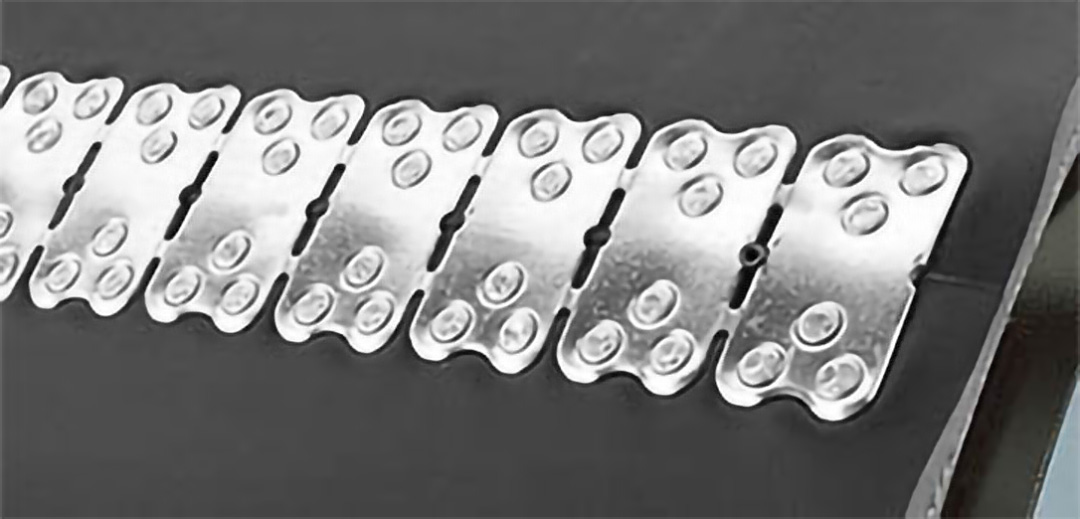

Bolt Solid Plate Fastener

The Bolt Solid Plate Fastening System creates a robust, sift-proof splice renowned for its exceptional holding capacity. This is achieved through a synergistic combination of top-and-bottom plate compression coupled with high-tensile-strength bolts.

Belt Details

Belt Thickness: 3/16" - 1-3/16"

PIW Max: 150 - 620 PIW

Min. Pulley Diameter: 12" - 48"

Bolt Hinged Fastener

The Bolt Hinged Fastening System is particularly suitable for belt conveyor applications that require frequent length adjustments, as the joint can be conveniently disconnected by removing the hinge pin. This system provides strength and dependability to belts running over smaller pulleys through a blend of penetration and compression.Belt Details

Belt Thickness: 1/4" - 5/8"

PIW Max: 190 - 300 PIW

Min. Pulley Diameter: 6" - 9"

Rivet Solid Plate Fastener

The Rivet Solid Plate Fastening System is designed for high-tension scenarios, featuring a staggered, multi-point attachment that ensures a durable and lasting grip. It is particularly effective for straight-warped belts as the rivets work by separating the fibers, rather than displacing the belt's carcass.

Belt Details

Belt Thickness: 7/32" - 15/16"

PIW Max: 400 - 800 PIW

Min. Pulley Diameter: 14" - 36"

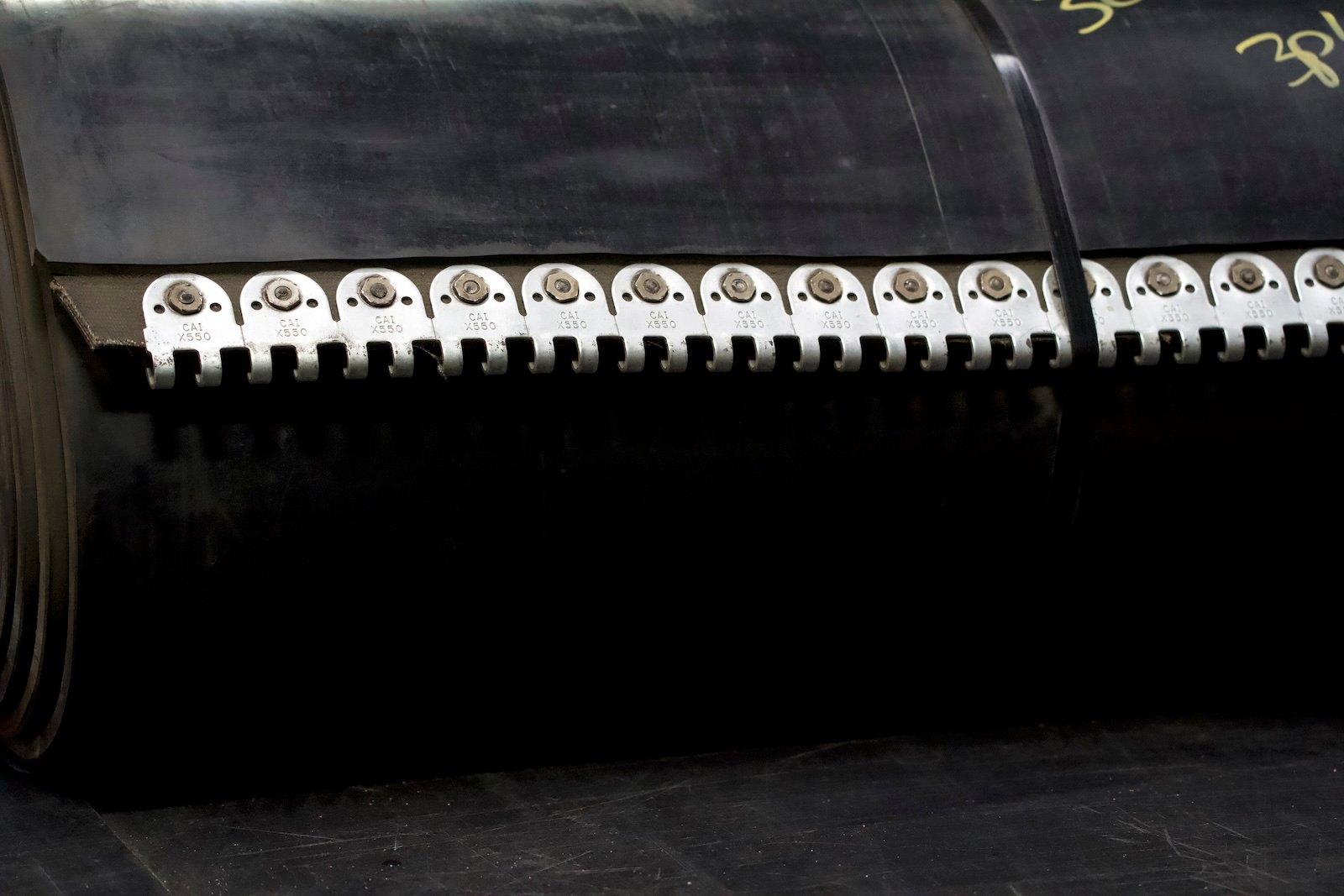

Riveted Hinged Fastener

The Rivet Hinged Fastening System is perfectly suited for rubber-plied and PVC solid woven belts, as well as for those belts too worn for vulcanized splices. It offers both high performance and longevity, along with the benefit of simple installation.

Belt Details

Belt Thickness: 1/8" - 1"

PIW Max: 330 - 2000 PIW

Min. Pulley Diameter: 5" - 42"

Staple Fastening System

The Staple Belt Fastening System merges an advanced applicator tool with the most durable staple fastener and hinge pin available, creating an exceptional belt splice that is especially suited for the demanding conditions of the mining industry.

Belt Details

Belt Thickness: 1/4" - 25/32"

PIW Max: 800 - 2000 PIW

Min. Pulley Diameter: 10" - 20"

Flexible Rubber Fastening System

The Flexible Rubber Fastening System stands out as a novel and inventive approach, serving as a vulcanization alternative in even the most challenging environments. This flexible splice attaches directly onto the belt with high precision and accuracy, providing a distinctive and unparalleled solution.

Belt Details

PIW Max: 0 - 1430 PIW

Min. Pulley Diameter: 6" - 20"

Clipper Wire Hook Fastener

The Clipper Wire Hook Fastening System is tailored to suit specific requirements, offering a range of wire diameters, leg and point lengths, types of metals, strip lengths, and styles, ensuring it meets the unique needs of your individual application.

Belt Details

Belt Thickness: up thru 25/64"

PIW Max: 200 PIW

Min. Pulley Diameter: 15/16" - 7"

Clipper G Series Fastener

The Clipper® G Series™ Fastening System ensures continuous compression, leading to a consistent, flat splice. Its unique staggered-leg design, featuring four varying leg lengths, offers enhanced strength and longevity to the completed splice.

Belt Details

Belt Thickness: 0.059" - 0.197"

PIW Max: 100 PIW

Min. Pulley Diameter: 1.6" - 3"

Clipper Laundry Patch Fastener

The Laundry Patch Fastening System integrates the attachment of cotton laundry tapes and the installation of fasteners into a unified process, which can be completed in about 20 seconds.

Belt Details

Belt Thickness: 0.078"

PIW Max: NA

Min. Pulley Diameter: 15/16"

Alligator Staple Fastener

The Alligator Staple Fastening System is excellently suited for a broad range of light to medium-duty fastener uses. This system is characterized by its one-piece fastener strips that come with pre-inserted staples, which facilitate faster installation and help to significantly reduce downtime.

Belt Details

Belt Thickness: 1/16" - 1/4"

PIW Max: 100 - 200 PIW

Min. Pulley Diameter: 2" - 4"

Alligator Lacing Fastener

The Alligator Lacing Fastening System is perfectly suited for the simple and cost-effective installation of a low-profile belt splice. Offered in continuous lengths, this system accommodates any belt width and ensures even tension distribution across the entire width of the belt.

Belt Details

Belt Thickness: up thru 1/2"

PIW Max: 25 - 200 PIW

Min. Pulley Diameter: 1" - 14"

Alligator Rivet Fastener

The Alligator Rivet Fastening System is uniquely tailored for the demanding task of round hay baling, streamlining belt maintenance and enhancing operational uptime.

Belt Details

Belt Thickness: 13/64" - 15/64"

PIW Max: 300 PIW

Min. Pulley Diameter: 3.5"

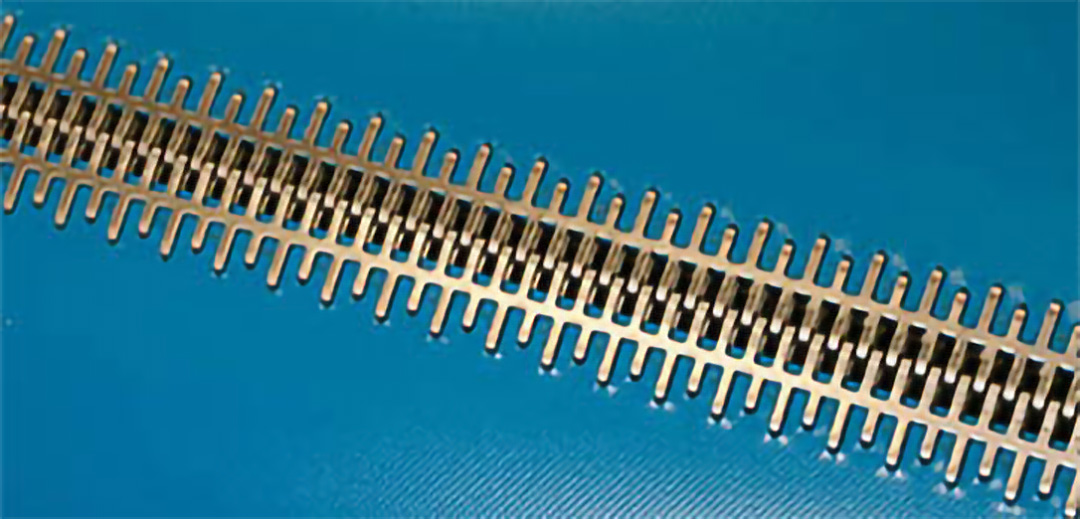

Spiral Lace Fastener

The Laundry Patch Fastening System integrates the attachment of cotton laundry tapes and the installation of fasteners into a unified process, which can be completed in about 20 seconds.

Belt Details

Belt Thickness: 1/16" - 3/16"

PIW Max: 50 PIW

Min. Pulley Diameter: 3/8" - 5/8"

Alligator Plastic Rivet Fastener

The Alligator Plastic Rivet Fastening System delivers a mechanically-applied splice that is non-scratching, non-magnetic, and operates quietly. It is also designed for easy disassembly, facilitating straightforward installation, cleaning, and sanitation processes.

Belt Details

PIW Max: 40-65 PIW

Min. Pulley Diameter: 1.5 - 3"

Alligator V-Belt Fastener

The V-Belt Fastening System is specifically engineered for application on machines that utilize fractional or multiple V-Belt drives.

Belt Details

PIW Max: NA

Min. Pulley Diameter: NA

Features & Benefits

Quick Installation

Reduced Maintenance Time

Versatility

Long-Term Reliability

Belt Varieties

Heavyweight Belt Fasteners

For heavy-duty applications like coal, cement, mining, and aggregate, two main belt fastener types are used: Hinged Plate and Solid Plate. Hinged plate fasteners, suitable for small pulleys, are inserted into each belt end, joined, and secured with a pin. Solid plate fasteners, ideal for larger pulleys and sift-free splicing, involve a single plate attached to both belt ends using bolts, rivets, or staples, depending on the belt type. These versatile fasteners, available in various metals, ensure reliable connections in demanding environments.

Lightweight Belt Fasteners

In light-duty applications such as agriculture, parcel handling, food, and laundry, our fasteners come in hook and lacing styles. Installation methods range from machine application to manual tools, and the fasteners are available in various materials, including metals, plastics, and food-grade options. Selecting the right mechanical belt fastening system is crucial for effective belt splicing.

Installation Tools/Equipment

Equipment

- Belt Clamps: Avoid the problems and potential dangers associated with homemade devices with belt clamps designed to properly secure and clamp a belt for safe conveyor maintenance.

- Belt Cutters: A properly squared belt discourages mistracking and splice failure, so utilizing a belt cutter that provides a straight cut is paramount to the splicing process. Our Belt Cutters minimize the danger of accidental injury during the belt-cutting process.

- Belt Lifter: Our Belt Lifter puts an end to pry bars and manual lifting, making a difficult and hazardous job easier and safer.

- Belt Skiver: A skived belt helps extend splice life, ensure compatibility with belt cleaners with a lower profile, and creates a stronger splice

Tools

- Bolt Breaker

- Boring Bit

- Power Boring Bit

- Hand Punch

- Power Punch

- Spanner Wrench

- Power Hex Spanner

- Power Socket Spanner

- Power Hex Wrench

- Power Socket Wrench

- Hand Hex Wrench

- Quick Change Chuck

Please let us know if any further adjustments are needed or if you require additional content for this specific page on mechanical belt fastening.

Belt Fastener Guide chart

Type |

Best For |

Strength |

Installation Method |

Description |

Applications |

Advantages |

Considerations |

Installation Tips |

|

#140 & #190 Plategrip Fastener |

General-Purpose Applications |

Moderate |

Bolted Plates w/ Hinge Pins |

Commonly used for general-purpose applications, the #140 and #190 Plategrip fastener features bolted plates with hinge pins for secure connections. |

Suitable for various industries and conveyor systems with general-purpose requirements. |

Reliable and versatile for general-purpose use. |

Regular inspection and maintenance are crucial. Consider the specific needs of the conveyor system. |

Follow the manufacturer's guidelines for proper installation. Check regularly for wear and signs of stress. |

|

Riveted Hinged Fastener |

Heavy-Duty Applications |

High |

Bolted Plates w/ Hinge Pins |

Ideal for heavy-duty applications like coal, cement, mining, and aggregate. Features bolted plates with hinge pins. |

Well-suited for industries with demanding conveyor systems. Suitable for applications requiring strong, durable connections. |

High strength, durable design suitable for demanding environments. |

Regular inspection and maintenance are crucial. Consider the specific needs of the conveyor system. |

Follow the manufacturer's guidelines for proper installation. Check regularly for wear and signs of stress. |

|

Lacing – Belt Fabrications |

Versatile Applications |

Moderate |

Multiple Attachment Methods |

Offers versatility in connecting conveyor belts. Utilizes various attachment methods for flexibility in different applications. |

Ideal for a wide range of industries and conveyor systems. Suitable for applications where flexibility and adaptability are essential. |

Versatile design, multiple attachment methods for flexibility. |

Consider the specific requirements of the conveyor system. Regular checks for wear and maintenance are necessary. |

Follow the recommended attachment method based on the application. Conduct regular inspections for signs of wear or stress. |

|

Self Lock Mechanical Fasteners |

Light to |

High |

Preassembled Plates & Pins |

Features pre-assembled plates and pins for easy installation. Suitable for a range of applications, from light to heavy-duty. |

Well-suited for applications in industries such as manufacturing, mining, and logistics. Ideal for conveyor systems with varying loads. |

High strength, easy installation with pre-assembled components. |

Ensure compatibility with specific conveyor system requirements. Regular maintenance checks are recommended. |

Follow the manufacturer's guidelines for proper installation. Conduct regular inspections for signs of wear or stress. |

|

MLT Clip'n Lock Hook Fastener |

Light-Duty Metal Applications |

Moderate |

Clip & Lock Mechanism |

Specifically designed for light-duty metal applications, utilizing a clip and lock mechanism for secure connections. |

Ideal for light-duty metal conveying applications, such as those in the food industry. Suitable for situations where a secure but lighter connection is required. |

Easy clip and lock mechanism, suitable for light-duty metal applications. |

Check the compatibility with the specific application and conveyor system. Regular maintenance checks are necessary. |

Follow the installation instructions provided by the manufacturer. Conduct regular inspections for wear and signs of stress. |

|

MLT Super-Screw Fastener |

Quick & Easy Installations |

High |

Hook & Lacing Styles |

Features a flexible rubber compound and can be quickly installed. Provides a strong connection without the need for extensive downtime. |

Suitable for applications where quick installation and minimal downtime are critical, such as in the aggregate and mining industries. |

Quick and easy installation, flexible rubber compound for versatility. |

Ensure compatibility with specific conveyor system requirements. Regular checks for wear and maintenance are necessary. |

Follow the provided installation guidelines for a quick and secure connection. Regularly inspect for signs of wear or stress. |

|

Fix N' Go Fastener |

Quick Repairs & Installations |

Moderate |

Combination of Plates & Pins |

Designed for quick repairs and installations, utilizing a combination of plates |

|

|

|

|

Our Mechanical Belt Fasteners are a dependable choice to ensure your conveyor systems operate efficiently and reliably. Whether you are in the mining, manufacturing, or agriculture industry, our fasteners are a smart and cost-effective solution. If you need assistance in selecting the right mechanical belt fastening system for your application, our team is here to help.