Hazemag

HAZEMAG is a world leader in impact crushing technology and processing systems, delivering industry-proven solutions for mining, cement, aggregates, and recycling. With this new alliance, Davis Industrial expands our offering to bring Florida operations easier access to high-performance Hazemag equipment — backed by local, boots-on-the-ground support from a team you already trust.

Features & Benefits

Access to Proven Equipment

Local Support. Faster Service.

Industry Expertise

One Stop - Conveyor & Crushing Solutions

HAZEMAG PARTS

As an official HAZEMAG dealer in Florida, Davis Industrial is your trusted source for genuine HAZEMAG parts.

From WEAR COMPONENTS to COMPLETE ASSEMBLIES , we supply everything you need to keep your HAZEMAG equipment running at peak performance. Whether it’s routine maintenance or urgent repairs, our team ensures fast access to the right parts — backed by expert support and reliable service.

HAZEMAG Equipment

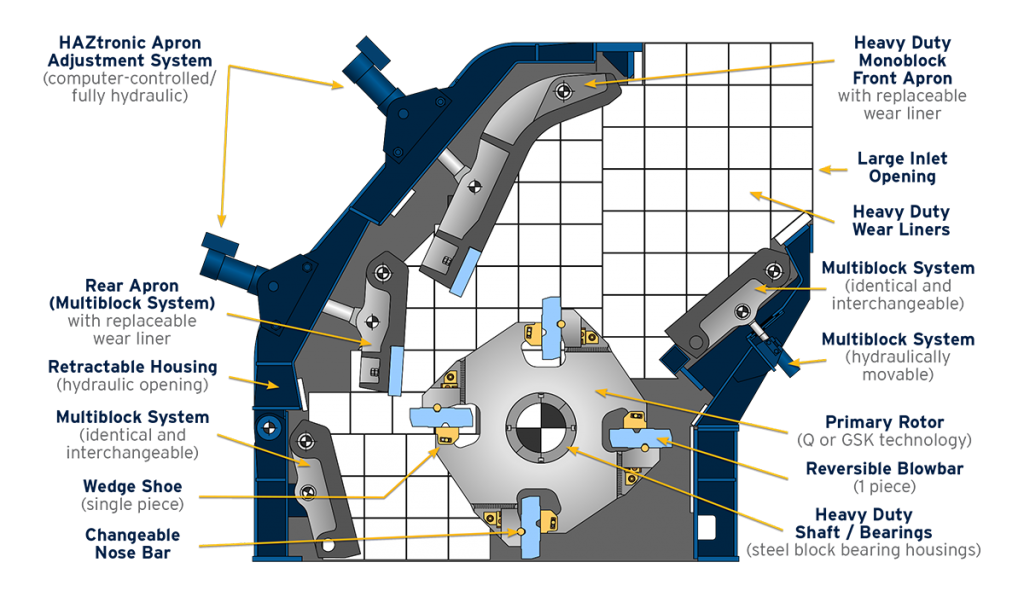

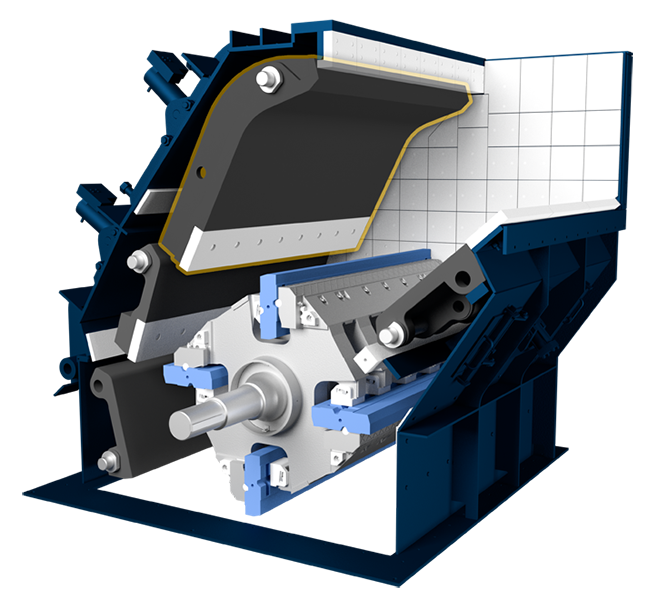

HPI – Primary Impactor

The HAZEMAG HPI Primary Impactor delivers exceptional performance in primary crushing, particularly for medium‑hard materials like limestone, concrete, and similar aggregates. Built for crushing large feed sizes in a single pass, it achieves high reduction ratios—often eliminating the need for secondary crushers. Available with hydraulically or electronically adjustable impact aprons (via Haztronic control), and optional grinding paths, the HPI ensures consistent, high-quality output, smooth operation, and robust safety features.

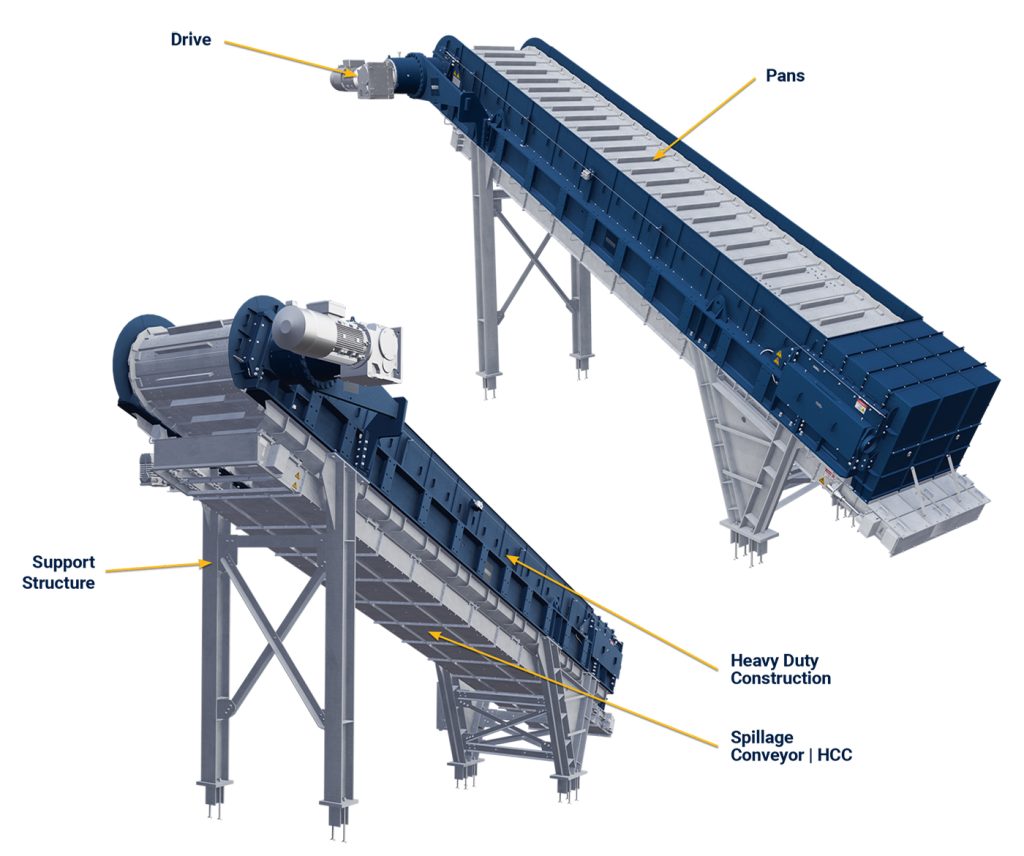

HAF – Apron Feeder

The HAZEMAG HAF Apron Feeder is engineered for reliable and efficient extraction of raw materials from feed hoppers in crushing plants. Featuring heavy-duty tractor chains, lifetime-lubricated components, and precision‑fitted overlapping pans, it offers high conveying capacities—up to 4,000 t/h with feed sizes up to 3 m³. Variable-speed drive ensures optimal plant utilization, while its low-wear design minimizes maintenance and maximizes uptime.

Primary Crushing Plants

HAZEMAG’s Primary Crushing Plants are available in stationary, mobile, and semi‑mobile, formats, designed for comprehensive primary crushing operations. They accommodate a range of crusher types—impact crushers, hammer crushers, sizers, and impact roll crushers—integrated with feed systems like wobbler or apron conveyors. These fully customizable systems deliver consistent, high-quality feed ideal for vertical roller mills or ball mills, offering a streamlined solution from material intake to output.

Industries / Applications we serve:

We have performed a lot of work in a variety of industries including; phosphate/fertilizer, gypsum wallboard manufacturing, aggregate, rock, citrus, wastewater, bauxite, sugar, sawmills/manufacturing, power, asphalt, concrete, recycling, and food/beverage. With Davis Industrial's custom approach, we can work with any industry that uses conveyors! Check out Davis Industrial, the best conveyor solution provider in Florida.