Product Inspection Equipment

We offer product inspection equipment solutions for a wide range of industries, our equipment is suitable for both dry and harsh wash-down environments. Whether you need to inspect dry goods, liquids, or anything in between, Davis Industrial has the piece of product inspection equipment for you. We are the best conveyor equipment provider in Florida!

Features & Benefits

Detects Physical Contaminants

Verifies Product Weights

Confirms Component Content

Inspects Closures

Versatile Applications

Industries / Applications:

Product Inspection Equipment from Davis Industrial is designed to cater to a wide range of industries and applications, providing versatile solutions for ensuring product safety and quality. Whether you're operating in the food and beverage, pharmaceutical, cosmetics and personal care, chemical, electronics, or automotive industry, our product inspection equipment is capable of detecting physical contaminants, verifying product weights, ensuring the accuracy of packaging and labels, confirming component content, inspecting closures, and measuring fill levels. We are conveyor experts and are well-equipped to provide the highest quality product inspection equipment.

Types of Product Inspection Equipment

Checkweighing:

Checkweighers are the best equipment for quality assurance. Today’s production operations are impossible without modern checkweighers. No matter whether you operate in the pharmaceutical, chemical, or cosmetic production industries, the food and beverage sector, the metal processing industry, or the automotive area – all companies rely on these precision instruments.

X-Ray Inspections:

X-Ray product inspection machines offer safety and quality assurance at every stage of the production process for raw, loose, pumped, and packaged products. Neither foil nor metalized film packaging affects the sensitivity of contaminant detection.

Metal Detection:

Metal detectors are designed to offer unrivaled levels of detection sensitivity to all metal contaminants. When integrated with materials handling and conveyor solutions, this complete range of industrial metal detectors provides fully automated product inspection for a wide range of food-processing applications.

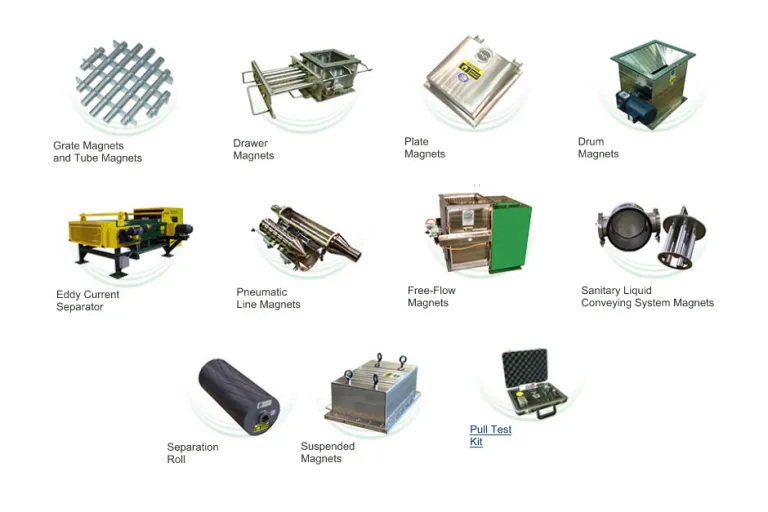

Magnetic Separation Equipment:

Magnetic separators are designed for maximum magnetic separation of metal contaminants, ranging from fine ferrous particles to large pieces of tramp iron. Used in a variety of industries to keep products clean and prevent damage to processing equipment.

Vision Inspection:

Vision inspection systems are for automated quality control of product labeling, information, and packaging. Vision systems detect irregularities, debris, functional flaws, and printing errors on product packaging and remove them from the production line.