Shaker Screens

At Davis Industrial, we offer a range of high-quality Shaker Screens designed for efficient and reliable separation of materials in various industries. These screens are engineered for optimal performance and are built to withstand the rigors of industrial applications, ensuring durability and longevity. Available in various sizes and configurations to meet your specific needs. Trust Davis Industrial, the best conveyor solution company in Florida, for top-notch Shaker Screens that will keep your operations on track.

Features & Benefits

Efficient Separation

Durability & Longevity

Versatile Configurations

Quality Assurance

Industries / Applications:

At Davis Industrial, our Shaker Screens are designed to meet the diverse needs of a wide range of industries and applications. Whether you're working in mining, construction, agriculture, or recycling, our screens are built to deliver efficient and reliable separation of materials. Davis Industrial offers the best conveyor equipment in Florida.

Replacement Screen Parts

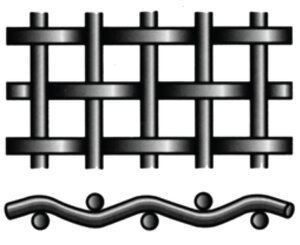

WOVEN WIRE STYLES

This widely used screen media offers a greater open area for throughput. Davis Industrial stocks hundreds of square opening screen sizes and can manufacture to your design specifications.

- Weave Styles

- Double-Crimp: A smaller opening weave style

- Loc-Crimp: A larger opening weave style for heavy applications

- Slotted Opening: Single-shute oblong opening for better flow

- Flat Top: May improve material flow with flatter surface than other weaves

- Tri-Loc/Tri-Mesh: Long openings help keep sticky or wet material flowing freely

- Intercrimp: Alternate choice for a wide range of non-standard slotted openings

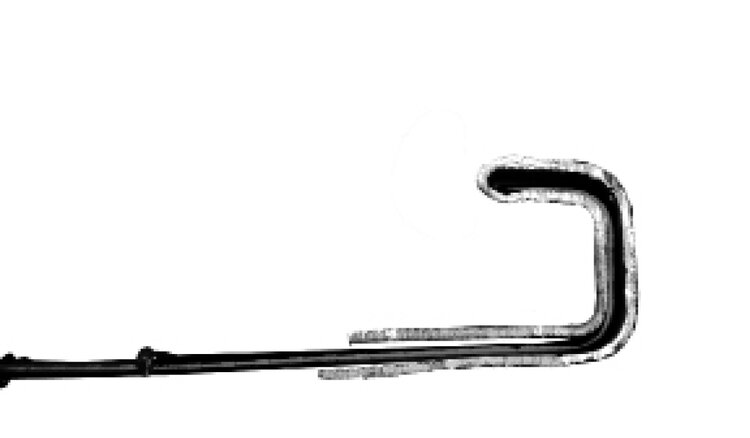

Hooks and Edge Protection

Plain Formed Edge

Plain Formed Edge for screens of 5/16” and larger diameter wire.

Edges are annealed by controlled heating before forming to eliminate cracking and breakage.

Reinforced Shroud Banded Edge

Reinforced Shroud Banded Edge is standard for screens of up to 3/8” wire diameter.

Standard shrouding is 18 gauge steel with other thicknesses available.

End Tension Reinforced Shroud Banded Edge

End Tension Reinforced Shroud Banded Edge is compatible with all OEM replacement applications. Excellent for .244” wire and lighter.

Hook lengths will vary to meet OEM specifications. Any dimension and profile is available upon request.

Square Hook

Any hook and angle will be manufactured to your specifications. Other hook dimensions are available upon request.

When ordering non-standard edges, give angle of formed edge and hook length.

*Custom hook edges available

Inside Reinforced Formed Edge

Inside Reinforced Formed Edge for screens of .313” diameter wire and larger can provide superior tensioning.

A 1/8” steel angle insert is welded inside the wire hooks, strengthening the screen for uniform tensioning and ease of installation on vibrating equipment. Also available in end-tensioned format.

Welded Bent Plate Edge

Welded Bent Plate Edge for 5/16” wire diameters and larger.

3/16” or 1/4” steel angle is welded on the screen edge.

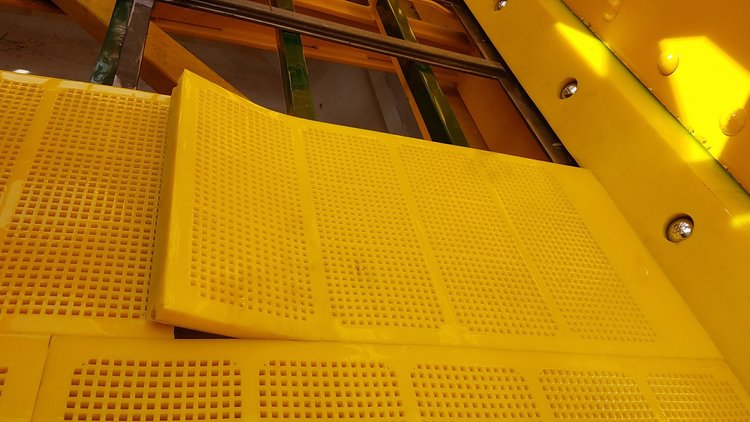

Polyurethane

Facilitating the metering or conveying of bulk materials discharged from centrifuges, filter presses, or mixers, the shaftless screw conveyor offers an efficient solution. Its design eliminates clogging, providing a smooth conveying surface that transforms the handling of challenging materials into a seamless process.

- Longer life – may last 15 to 20 times the life of wire cloth

- Reduced plugging and blinding; better production performance

- Tapered openings allowing for material to break away

- Openings ranging from 0.3mm to 152mm, (0.01” to 6”)

- 30mm to 70mm thick modules; can include dams and diverters

- Variety of materials available; ethers or esters ranging from 60A to 90A durometer

- Assortment of urethane modules offered, for the diverse collection of polyurethane screening systems

- Custom module fabrication available

Rubber

Looking for a modular rubber system for high-impact applications, processing dry materials, scalping applications?

- Costs less than polyurethane and lasts longer than wire cloth.

- Permanent or removable systems are available.

- 1’ x 2’ module panels are standard with other sizes available.

Applications

- Sizing, washing

- Feed zone on portable plants

- Can replace wire cloth easily, no modification needed

- Both hooks up or both hooks down

- One hook up, and one hook down

- Custom designed screen size to fit any deck

- 1.00” Standard thickness

- Precision made wire cloth internal structure

- Available opening sizes from .750” to 2.00”

- Available in 40 durometer and 65 durometer rubber