Pulleys & Pulley Accessories

We offer a comprehensive selection of pulleys and pulley accessories to enhance the efficiency and reliability of your conveyor systems. Trust Davis Industrial as your go-to source for high-quality conveyor components to ensure the smooth operation of your conveyor systems

Pulley Applications:

Davis Industrial's pulleys and pulley accessories are engineered to provide versatile solutions across a wide spectrum of industries, contributing to efficient material handling and conveyor system functionality. These adaptable pulleys find application across multiple industries, supporting the seamless flow of materials. Whether it's optimizing material handling in manufacturing, enhancing logistics and distribution operations, or facilitating efficient processes in general material handling scenarios, our pulleys offer broad applications.

Features & Benefits

Diverse Pulley Types

Choose from a diverse range of pulleys, including head pulleys, snub pulleys, and more, catering to the specific requirements of your conveyor system.

High-Quality Materials

Davis Industrial's pulleys are sourced from manufactures that use high-quality materials, ensuring durability and longevity even in challenging operational environments.

Customization Options

Tailor your conveyor systems with our customizable pulley options. We offer solutions that can be adapted to different belt widths, speeds, and configurations.

Reduced Maintenance

Davis Industrial's pulleys are designed for minimal maintenance, contributing to cost-effective and hassle-free conveyor system operation.

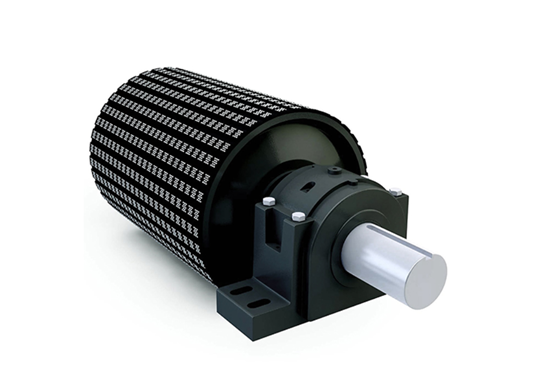

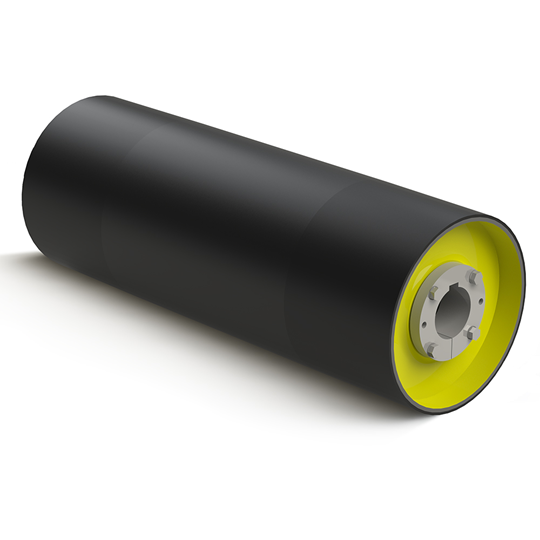

Pulley Assemblies

ENGINEERED DRUM PULLEY ASSEMBLIES

At Davis Industrial, our Engineered Drum Pulley Assemblies are made from high-quality materials, these pulleys are built to withstand the demands of industrial applications. We can modify your drum pulleys to be custom-tailored to meet your specific requirements. Trust Davis Industrial for all your engineered drum pulley needs, and keep your conveyor systems running smoothly and efficiently.

Features & Benefits

Drum pulleys are among the most adaptable elements of a conveyor system. Based on their specifications, they can function in several roles or positions, such as drive or head, return or tail, bend tensioning, snub tensioning, and/or take-up pulleys. Our team of experts can craft your desired drum pulley to fulfill your conveyor solution needs. These various roles can either increase or decrease the slack in your conveyor belt, depending on the specific requirements of your system.

Key Industries & Applications

Head, snub, bend, and take-up pulleys on bulk belt conveyors can be used in any industry that requires conveyor solutions. The Engineered Drum Pulleys are customizable, so Davis Industrial can make drum pulleys work for you. Industries like metallic mining, stone, clay, glass, cement, coal mining and preparation plants, coal-fired electric generating plants, transportation ports, and much more can all benefit from Davis Industrial's engineered drum pulley assemblies.

Complementary Dodge Products

- Couplings

- Pillow Block Bearings

- Take-up Frames

- Gear Reducers

- Electric Motors

Modifications Available

- Shafts with turn downs, keyways, holes drilled and tapped supplied with nonwater soluble rust inhibitor

- Mounting of shafts to pulley hubs, bearings and coupling halves mounted to shafts

- Drums center crowned or straight faced

- Spiral rods or bars welded to drums

- Turned rim outside diameters to .015 TIR, post weld thermal stress relieving, static balancing to ISO Standard 1940/1-1986 (Grade G-40), dynamic balancing, magnetic particle and ultrasound weld testing, and line boring of end disc inside diameters

- Certified, reproducible drawings furnished

HEAVY DUTY DRUM PULLEY ASSEMBLIES

Our heavy-duty drum pulley assemblies are sourced from the highest quality manufacturers. Our drum pulley assemblies are durable and provide optimal performance in the most demanding material handling environments. Trust Davis Industrial as your provider of the best conveyor components on the market!

Features & Benefits

- Reduced Maintenance: The robust design and quality construction minimize the need for frequent maintenance, reducing downtime and ensuring continuous conveyor operation.

- Versatile Applications: Suitable for a variety of industries, these assemblies can be customized to meet specific conveyor requirements, making them a versatile solution for diverse material handling needs.

- USA Made: We take pride in sourcing these pulley assemblies from American manufacturers, ensuring the highest-quality craftsmanship, supporting local industry, and providing customers with American-made reliability.

Key Industries & Applications

- Material Handling: Whether it's moving bulk materials in manufacturing plants, warehouses, or distribution centers, these pulley assemblies excel in ensuring the seamless flow of materials.

- Mining and Quarrying: Ideal for conveying heavy materials in mining and quarrying operations, these pulley assemblies provide the strength and durability needed for demanding applications.

- Aggregate and Construction Industries: Where robust components are essential for handling a variety of materials, our assemblies deliver reliable performance.

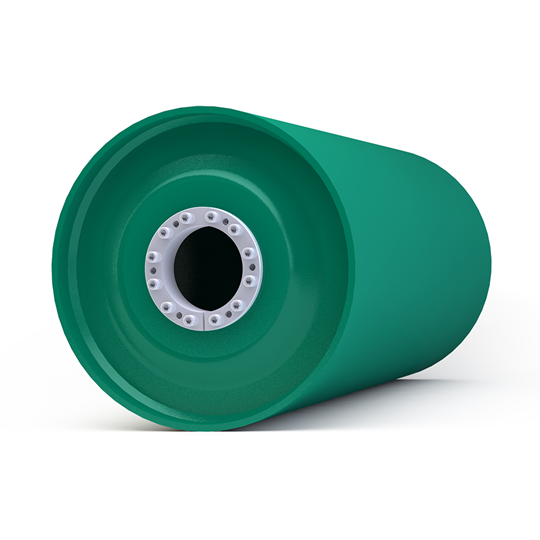

HEAVY DUTY MAGNETIC DRUM PULLEY ASSEMBLIES

Our heavy-duty magnetic drum pulley assemblies are designed for efficient ferrous metal separation in conveyor systems. Davis Industrial offers the best conveyor components on the market.

Features & Benefits

- Versatile Applications: Suitable for a wide range of industries, these assemblies excel in applications such as mining, recycling, aggregate processing, and more, where ferrous metal removal is critical.

- Easy Installation and Maintenance: Davis Industrial is your all-in-one partner for conveyor systems. We will be your guide on installation, support, maintenance, and emergency repairs.

Key Industries & Applications

Our heavy-duty magnetic drum pulley assemblies offer versatile solutions for numerous industries seeking efficient material separation in conveyor systems.

- Material Processing: Whether handling minerals, aggregates, or recycled materials, our magnetic drum pulley assemblies efficiently remove ferrous contaminants, contributing to the purity and quality of processed materials.

- Manufacturing: In manufacturing settings, these assemblies aid in the separation of ferrous metals from raw materials or finished products, ensuring product integrity and protecting machinery.

- Construction and Demolition: Ideal for construction and demolition projects, these pulley assemblies assist in the extraction of metal debris from demolished materials, minimizing equipment wear and enhancing safety.

- Waste and Recycling: From municipal waste facilities to specialized recycling centers, our assemblies contribute to the extraction of ferrous metals, promoting recycling efficiency and reducing the impact of contaminants.

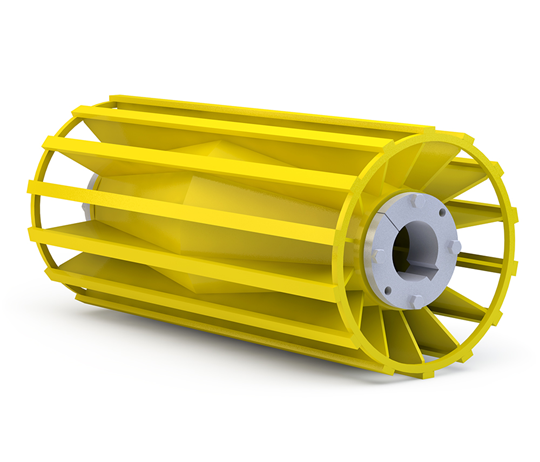

HEAVY DUTY WING PULLEY ASSEMBLIES

Our heavy-duty wing pulleys are sourced from the highest-grade manufacturers around, these pulleys are designed to enhance belt tracking and material handling. Davis Industrial prides itself on being a quality partner for all of your conveyor needs.

Features & Benefits

- Enhanced Belt Tracking: The wing design of these pulleys improves belt tracking, reducing the risk of misalignment and extending the life of conveyor belts.

- Optimized Material Handling: These pulleys contribute to optimized material handling processes by promoting smooth and efficient movement of conveyed materials, enhancing overall conveyor system performance.

- Easy Installation and Maintenance: As your all-in-one partner, Davis Industrial will help with installation, support, maintenance, and any emergency repairs.

Key Industries & Applications

Our wing pulleys offer versatile solutions applicable to a wide range of industries, including manufacturing, mining, construction, recycling, agriculture, power generation, and bulk handling. Davis Industrial is committed to supporting the diverse needs of industries seeking reliable and adaptable solutions for their conveyor systems.

MINE DUTY EXTRA WING PULLEY ASSEMBLIES

We provide mine duty extra wing pulleys sourced from top manufacturers, delivering a robust and reliable solution for mining conveyor systems. Designed for heavy-duty applications, these pulley assemblies ensure strong material handling in demanding mining environments.

Features & Benefits

- Reliable Performance: Our drum pulleys provide reliable and consistent performance, contributing to the smooth operation of your conveyor systems.

- Reduced Maintenance Downtime: The robust construction and high-quality components of these pulley assemblies contribute to reduced maintenance requirements, minimizing downtime in critical mining operations.

Key Industries & Applications

These drum pulleys are tailored to the mining industry, where reliable and durable components are critical for efficient material handling. These pulley assemblies are suitable for various mining applications, including the transport of bulk materials, minerals, and ores. Davis Industrial is your trusted partner for all things conveyors, from installation, to emergency repair.

MINE DUTY EXTRA DRUM PULLEY ASSEMBLIES

We offer a comprehensive selection of mine duty extra drum pulleys, sourced from reputable manufacturers known for their quality and durability. These pulleys deliver robust performance and reliable material handling in heavy-duty conveyor systems. Davis Industrial is a leader in providing quality parts for your conveyor systems.

Features & Benefits

- Consistent Performance: Our wing pulleys deliver consistent and reliable performance, contributing to the optimal operation of mining conveyor systems.

- Heavy-Duty Build: Our wing pulleys feature heavy-duty construction to withstand the rigorous demands of mining environments, ensuring durability and longevity in high-load applications.

- Ease of Integration: With the help from our expert conveyor technicians, integrating these pulleys into your conveyor system is easy. Our technicians can help you with installation, maintenance, and emergency repairs. This is what makes Davis Industrial a leading conveyor partner in Florida.

Key Industries & Applications

These wing pulleys are tailored for the mining industry, and address the need for durable and reliable components in conveyor systems. Our wing pulleys find applications in various mining processes. Davis Industrial ensures that mining operations receive high-quality components and support to meet their specific conveyor system requirements.

Pulley Assemblies

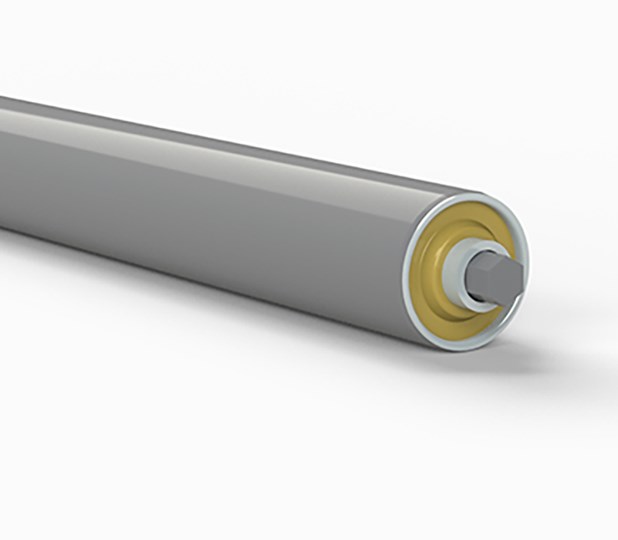

Hex Rollers

Used throughout the unit and package handling industries, our hex rollers are sourced from top quality manufactures.

Features & Benefits

- Flat faced or Crowned

- 1.9”, 2”, 2.5” Diameter

- Carbon Steel, Galvanized Steel, PVC

- 7/16” & 11/16” Hex Shaft

- 16 ga, 14 ga, 11 ga Steel options

- .145” wall PVC

- Shaftless, Secured, Spring Loaded Shafts

Key Industries & Applications

Hex Rollers are key components to have in the unit and package handling industries.

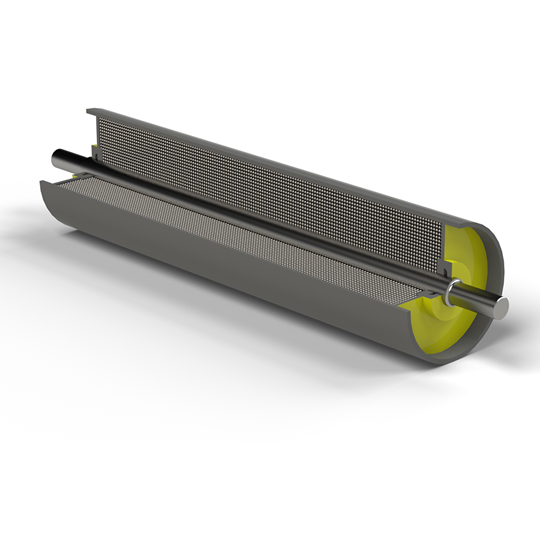

Hush Roll

The current one-piece steel return rolls create excessive noise due to the belt running over a tube at high speeds, causing vibrations. The Hush Roll is a great solution to quieter working conditions and to improve overall workplace safety.

Features & Benefits

- Emits a quarter of the sound of the traditional return roll

- Multiple belt contact points design for safety

- Drop in ready to replace 2.125” return rolls.

Key Industries & Applications

The Hush Roll can be used in a variety of different industries. Make your workplace safer and quieter with the Hush Roll!

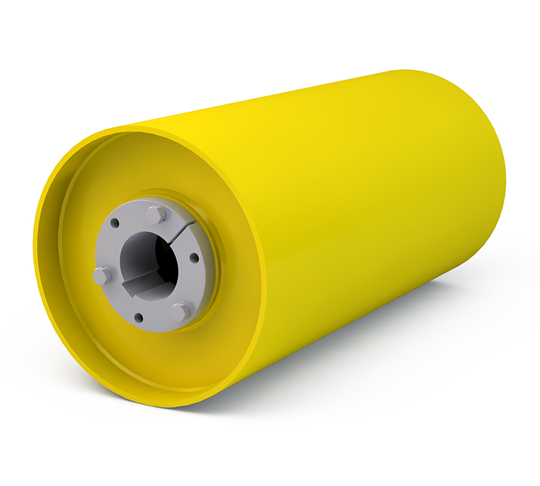

Unit Handling Pulleys

We have the capabilities to engineer and customize pulleys to fit your needs. Davis Industrial will be your all-in-one conveyor partner and give you a turn key solution.

Features & Benefits

- Customizable

- Smooth

- Consistent

- Reliable performance

- Small in diameter

Key Industries & Applications

Our Unit Handling Pulleys are totally customizable. You tell us your need and we will make it happen!

Unit Handling Rollers

We have the capabilities to engineer and customize rollers to fit your needs. Davis Industrial will be your all-in-one conveyor partner and give you a turn key solution.

Features & Benefits

- Customizable

- Smooth

- Consistent

- Reliable performance

- Small in diameter

Key Industries & Applications

Our Unit Handling Rollers are totally customizable. You tell us your need and we will make it happen!

Custom Products

Davis Industrial gives you an all-in-one solution to your conveyor needs, that means if you have a need we will figure out a solution! We can create custom pulley products to seamlessly fit your businesses operations.

Features & Benefits

- Endless unusual designs

- Custom built

- A pulley product designed specifically for your workplace

Key Industries & Applications

A 100% custom solution, so matter your industry or application, Davis Industrial can help!

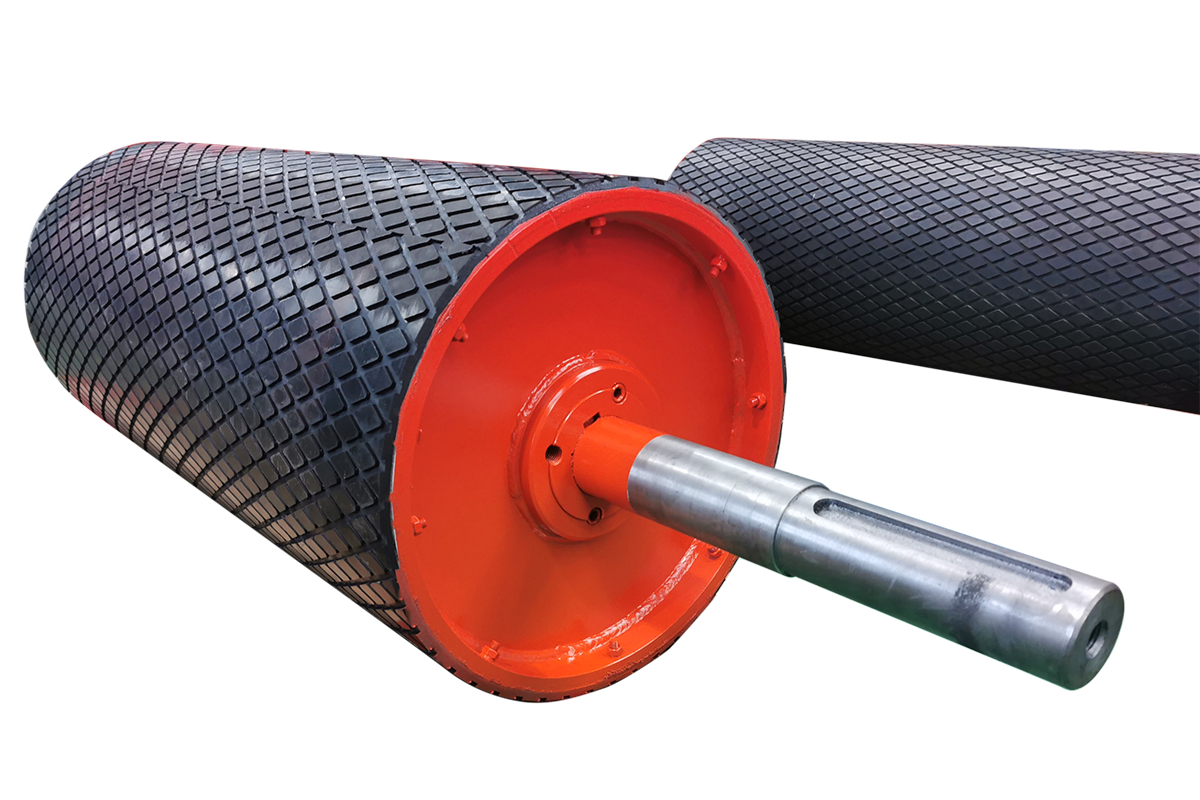

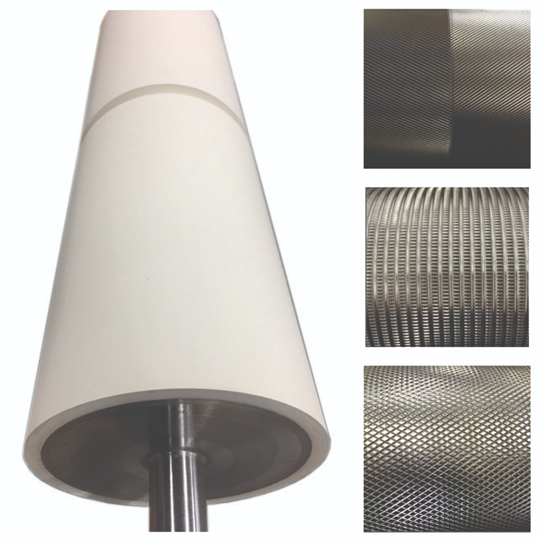

Lagging & Knurling Options

Lagging involves applying an elastomer compound to a pulley's face to enhance friction, minimizing belt slipping and required tension for conveyor drive

Features & Benefits

- Longer belt and component life

- Increased reliability

- Greatly reduces wear caused by abrasive materials

- Prevents buildup of sticky material on pulley services

Key Industries & Applications

Lagging and Knurling Pulley options can be used across all lightweight industries and applications.

Static End Rollers

Static End Rollers are designed to eliminate the potential pinch point caused between a rotating roller and the moving conveyor belt.

Features & Benefits

- Static end design eliminates pinch points between belt and roller

- Reduces entanglement of foreign objects and debris

- Increases safety and reliability

Key Industries & Applications

Static End Rollers are crucial components to have in any lightweight industry because it increases the safety and efficiency of your conveyor systems.

Tight Transfer Rollers

Tight Transfer Roller for high load unit handling applications. The 2.25” roller diameter is great for conveying applications requiring minimum gap to reduce package movement on belts operation in excess of 540 feet per minute.

Features & Benefits

- 2.25” edge crown tube

- ½-13 UNC bolt attachment point

- 1-1/8” Hexagonal shaft end for easy bolt tightening

- Sealed for life

- Increased bearing life

Key Industries & Applications

The Tight Transfer Roller is perfect for the package handling industry. The 2.25" roller diameter allows you to transfer packages without the risk of damaging them.

Weighted Take-up Pulleys

Weighted take up pulleys help take slack out of the belt.

Features & Benefits

Key Industries & Applications

The Tight Transfer Roller is perfect for the package handling industry. The 2.25" roller diameter allows you to transfer packages without the risk of damaging them.

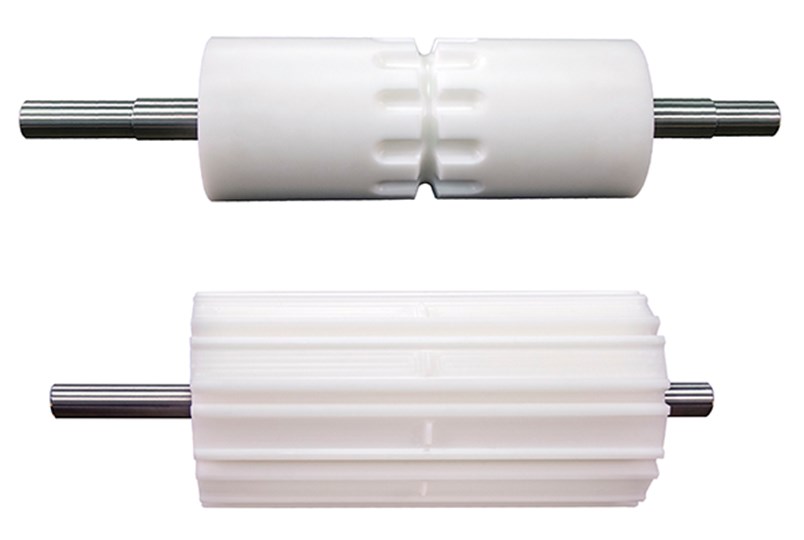

SANITARY DRIVE PULLEYS

Drop-in replacement for square shaft driven solutions.

Features & Benefits

- Positive drive system

- Self-tracking belt

- Low-maintenance

- Quiet operation

Key Industries & Applications

Sanitary Pulleys can be built to accommodate different styles of positive drive conveyor belting as a drop-in replacement for square shaft driven solutions.

SANITARY TAIL PULLEYS

Drop-in replacement for traditional square shaft driven solutions.

Features & Benefits

- Positive drive system

- Self-tracking belt

- Low-maintenance

- Quiet operation

Key Industries & Applications

Sanitary Pulleys can be built to accommodate different styles of positive drive conveyor belting as a drop-in replacement for square shaft driven solutions.

SELF-LEVELING FOOT PADS

Self-leveling pads offer some of the best leveling options in the industry. Made of all stainless-steel, our pads have a sanitary design and a heavy load rating.

Features & Benefits

- Available in a wide variety of standard sizes and lengths

- Carrying capacities of up to 28,000 lb.

Key Industries & Applications

Our Self-Leveling foot pads are an all stainless steel, sanitary design allowing for use in food production applications.

STAINLESS-STEEL BUSHINGS

A pulley assembly is only as good as the components that go into it!

Features & Benefits

- Available in XT, QD and taper-lock

- Quality stainless-steel

Key Industries & Applications

Stainless-Steel Bushings are perfect for all light weight applications.

Pulley Accessories

Apron Feeder Shaft

Apron feeders serve as a widely employed method for the controlled feeding of materials. Typically located beneath primary jaw or gyratory crushers, stockpiles, or rail unloading stations, they commonly utilize dozer chains due to their strength and reliability.

Features & Benefits

- Our expert technicians can customize the Apron Feeder Shafts to fit your businesses needs

- Designed for long wear and maintenance-free service

Key Industries & Applications

Used in copper, gold, cement and other types of mining operations providing ultimate reliability.

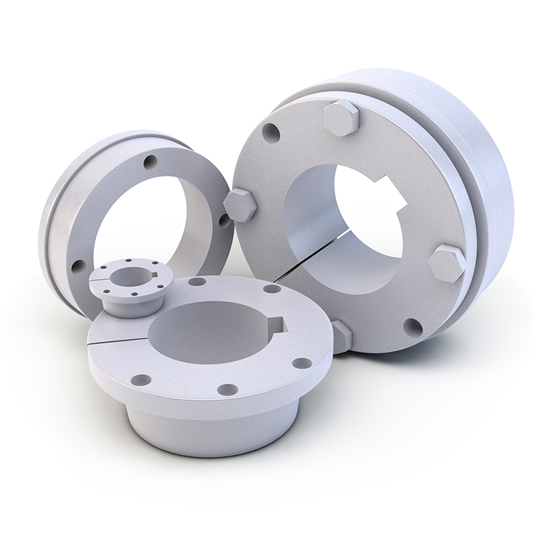

Bushings

Computer-designed and specifically developed for conveyor pulley applications

Features & Benefits

- 3/4” -2” per foot taper

- Self-seating – no need to hammer bushing in

- Designed for a wide variety of applications

High clamping force eliminates need for keyway on non-drives

Bolts equally spaced for even draw-up

Full length hub engagement

Flange deflection stores up cap screw torque for seating while running

Easy removal

Full size keys in max bores for size 50 and larger

Key Industries & Applications

Our Bushings work across a wide variety of industries. They have more than enough holding power for your conveyor pulleys.

Keyless Locking Assemblies

A single taper design better equipped to handle the bending in pulley applications.

Features & Benefits

- Self-centering

- No pilot bushing needed

- The single taper design is better able to handle the bending movement present in pulley applications

Key Industries & Applications

The Keyless Locking Assemblies is perfect for a variety of pulley applications. It was specifically developed to support high torque and bending in pulley applications.

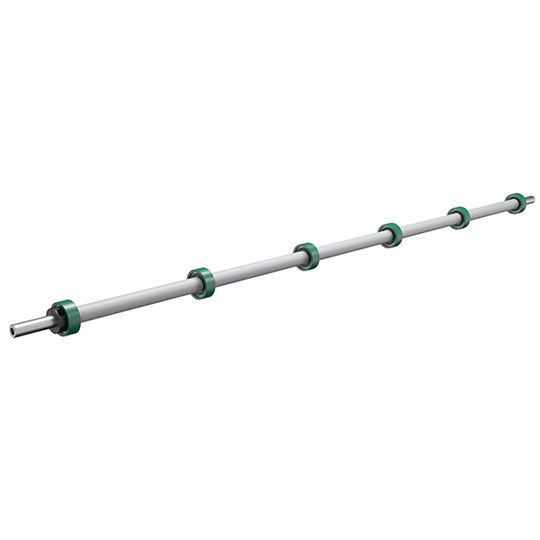

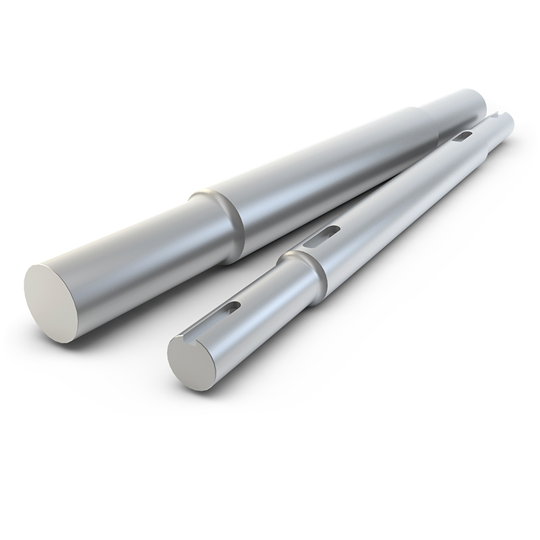

Shafting

Davis Industrial conveyor pulley shafting are a vital part of the total pulley assembly.

Features & Benefits

- Made of very strong steel that machines to a smooth finish

-

Full machining and milling capabilities

AISI 1045 is the standard shafting materialShafting can be customized by our team of expert technicians

Key Industries & Applications

Shafting is crucial in the pulley assembly. No matter your industry, Davis Industrial can serve you!