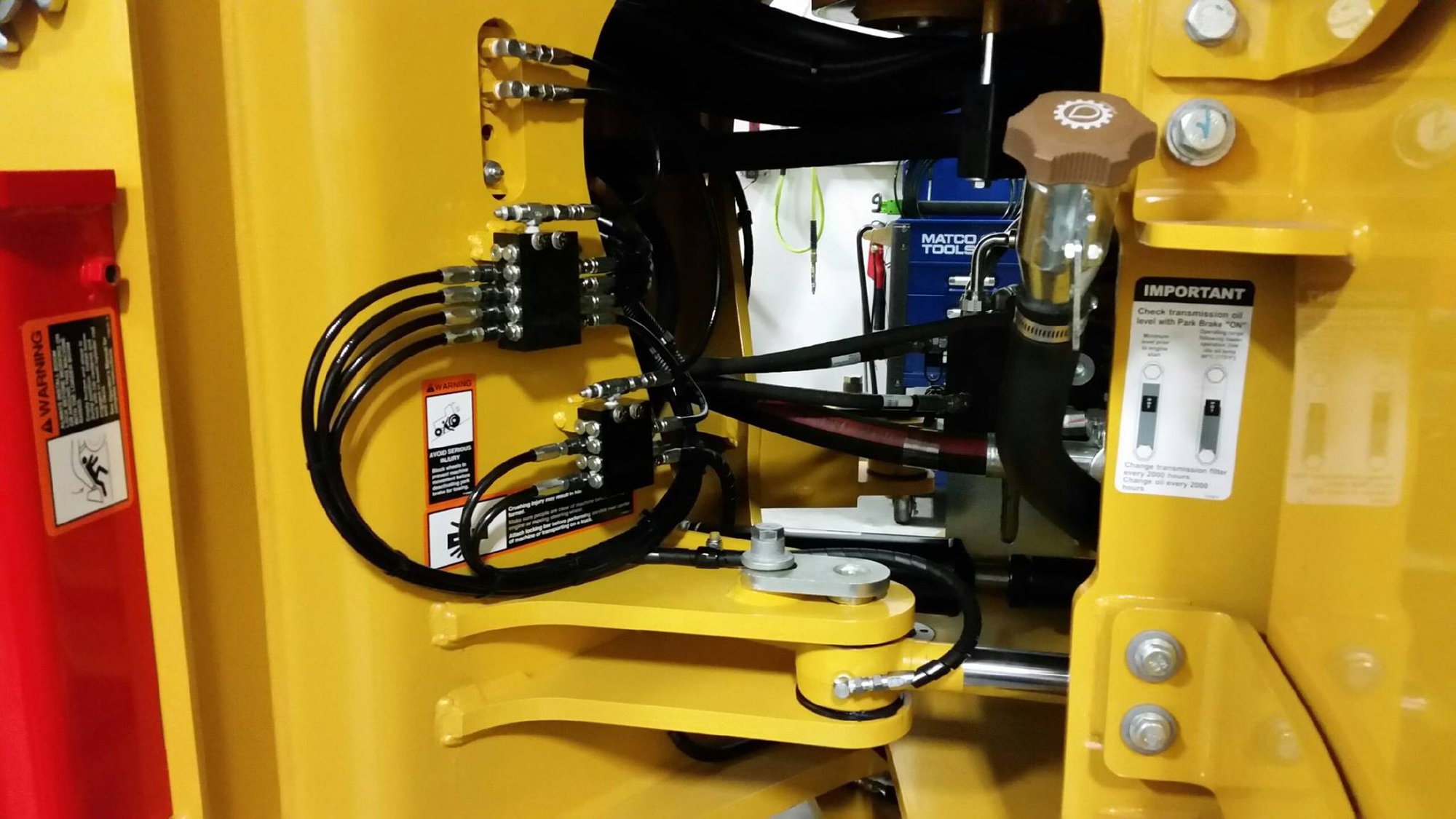

Automated Lubrication Systems

We offer high-quality Automated Lubrication Systems designed to provide consistent and reliable lubrication to machinery and equipment in various industries and applications. These systems automatically deliver the lubricant to critical components at the right time, reducing friction and wear, and extending the life of your equipment. Davis Industrial provides top-notch Automated Lubrication Systems that will keep your equipment running properly.

Features & Benefits

Reliable & Efficient

Increased Productivity

Safe & Easily Accessible

Industries / Applications:

Automated Lubrication Systems offered by Davis Industrial are used across a wide range of industries and applications to provide consistent and reliable lubrication to machinery and equipment. These systems are commonly used in sectors such as manufacturing and production, where they are employed to lubricate various types of machinery, including CNC machines, presses, and conveyors. We have a team of experts that can customize our lubrication systems to fulfill your needs, no matter the industry. Check out Davis Industrial, the best all-in-one solution for your conveyor system needs.

Individual Point Lubrication

Our auto greaser is designed for single-point lubrication of roller and slider bearings, shaft seals, and chains. With discharge settings ranging from 1 to 12 months, it facilitates timely greasing cycles to extend the life of conveyor components. The built-in sensor measures ambient temperature, allowing the control unit to calculate precise gas generation for continuous and controlled discharge.