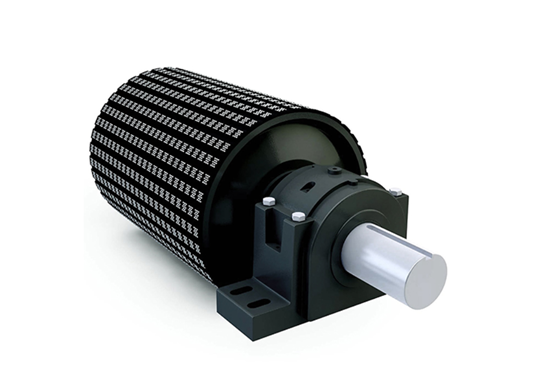

engineered drum pulley assemblies

At Davis Industrial, our Engineered Drum Pulley Assemblies are made from high-quality materials, these pulleys are built to withstand the demands of industrial applications. We can modify your drum pulleys to be custom-tailored to meet your specific requirements. Trust Davis Industrial for all your engineered drum pulley needs, and keep your conveyor systems running smoothly and efficiently.

Features & Benefits

Drum pulleys are among the most adaptable elements of a conveyor system. Based on their specifications, they can function in several roles or positions, such as drive or head, return or tail, bend tensioning, snub tensioning, and/or take-up pulleys. Our team of experts can craft your desired drum pulley to fulfill your conveyor solution needs. These various roles can either increase or decrease the slack in your conveyor belt, depending on the specific requirements of your system.

Industries / Applications:

Head, snub, bend, and take-up pulleys on bulk belt conveyors can be used in any industry that requires conveyor solutions. The Engineered Drum Pulleys are customizable, so Davis Industrial can make drum pulleys work for you. Industries like metallic mining, stone, clay, glass, cement, coal mining and preparation plants, coal-fired electric generating plants, transportation ports, and much more can all benefit from Davis Industrial's engineered drum pulley assemblies.

Complementary Dodge Products:

- Couplings

- Pillow block bearings

- Take-up frames

- Gear reducers

- Electric motors

Modifications Available:

- Shafts with turn downs, keyways, holes drilled and tapped supplied with nonwater soluble rust inhibitor

- Mounting of shafts to pulley hubs, bearings and coupling halves mounted to shafts

- Drums center crowned or straight faced

- Spiral rods or bars welded to drums

- Turned rim outside diameters to .015 TIR, post weld thermal stress relieving, static balancing to ISO Standard 1940/1-1986 (Grade G-40), dynamic balancing, magnetic particle and ultrasound weld testing, and line boring of end disc inside diameters

- Certified, reproducible drawings furnished