Conveyor Monitoring Equipment

Understand the current condition of your conveyor systems at all times with our conveyor monitoring equipment. We offer a variety of conveyor monitoring products that use innovative technology to give you the insight you need to maintain your conveyor systems.

Features & Benefits

Real Time Insights

Belt Health Tracking

Downtime Minimization

Predictive Maintenance

Types of Monitoring Equipment

- Belt Monitoring: Our conveyor belt monitors use proximity sensors that create an electronic pulse stream to control shutdowns and warning alert systems.

- Idler Monitoring: Our idler monitor uses advanced technology to predict and report idler failure.

- Versatile Monitoring Solutions: Some conveyor monitoring products can be applied to a range of applications, for example, our magnetic coupling system can be easily attached to a variety of conveyor systems to monitor different potential issues.

Available Equipment

Smart Roll

Conveyor belt monitor that is designed with a proximity sensor to monitor belt speed

Features & Benefits

- Sensor Protection

- Overload Protection: Protects the sensor from short circuits, controls shutdowns, employs warning signals, and wiring problems

- Maintenance Free

- Versatile: Longer life due to no load and flexible mounting

Speed Switch

Make installing conveyor monitoring a breeze with the Speed Switch. Forget about drilling and tapping – just snap the sensor onto the shaft, connect the wiring, and you're done. Plus, the magnetic coupling ensures the unit breaks away if hit by debris, protecting your equipment better than rigid designs.

Features & Benefits

- Installs in seconds by utilizing a user friendly magnetic design to attach to the shaft

- Reduces costly set up & installation time by eliminating the need for a drill and tap

- Break away design minimizes equipment damage from falling debris compared to a rigid design

- Rugged nylon housing is nearly indestructible and will withstand the harshest environments

- Visually monitor proper function via an illuminated LED

- Interfaces with most PLCs

- Handles a wide variety of input voltages from 20-240V AC/DC

Vayeron Idler

The Vayeron Idler is able to predict and report idler failure.

Features & Benefits

- Autonomous and online 24/7 monitoring

- Predictive maintenance insight

- Pre-emptive detection of idler failure

- Increased safety

- Reduced downtime

- Reduction in spares inventory

- Increased productivity

- Improved operational data

Watch Dog

The Watch Dog is designed to monitor a pulse stream received from a speed monitoring device.

Features & Benefits

- Functions as an adjustable under-speed detector

- AC snubber provided

- Operates on AC or DC voltage

- Adjustable timing range

- DIN rail compatible

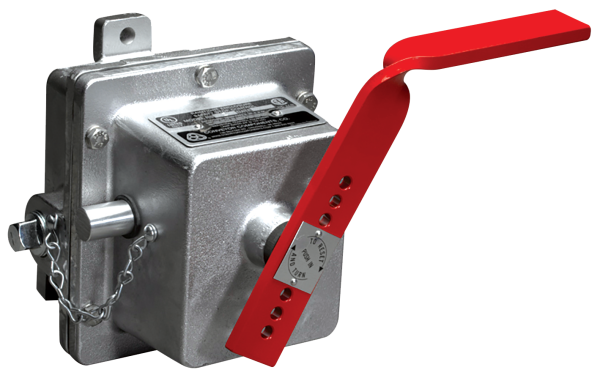

E- STOP SWITCH

The Model RS is a heavy-duty safety control that provides a positive shut off of dangerous equipment in an emergency. A cable pulled by endangered personnel actuates the control.

Benefits

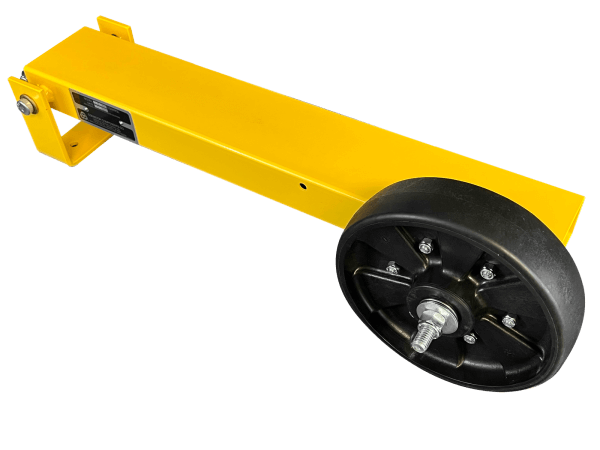

MIS-ALIGNMENT BELT SWITCH

This heavy-duty conveyor belt mis-alignment switch that either provides an indication or a shut off of the conveyor during a drift condition in order to prevent further damage to the conveyor belt. The output contacts of the Model BA can control up to two separate circuits, one for conveyor shutdown and one for an alarm.

Benefits

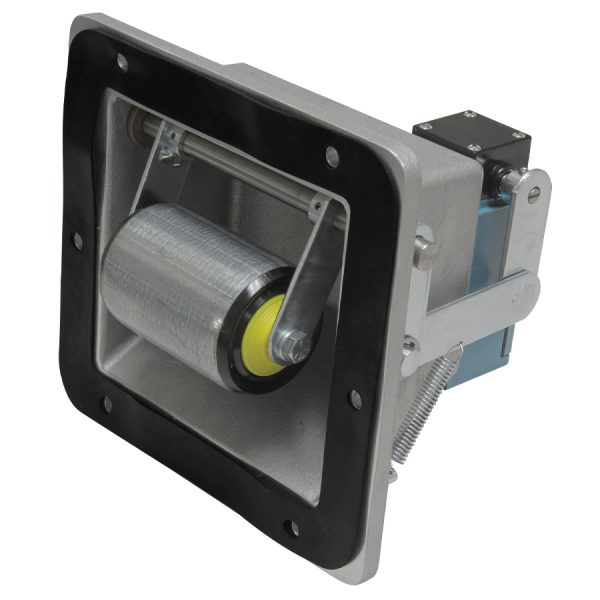

motion control

This model is a “traction action” motion control that indicates when a conveyor belt has slowed or quit moving altogether. The unit can be adjusted as an overspeed, under speed, or zero speed control.

Benefits

Belt misalignment indicator

The belt misalignment control indicating when a conveyor belt has drifted off to a dangerous condition. The output contacts of the Model TA can control up to two separate circuits, one for machinery shutdown and one for an alarm.

Benefits

Belt misalignment switch - bucket elevator

The Model VA is the newest belt alignment control specifically designed for use with bucket elevators. The unit is typically used in pairs to provide protection to both sides of the elevator leg, and indicates when the vertical belt strays or drifts beyond acceptable limits.

Benefits

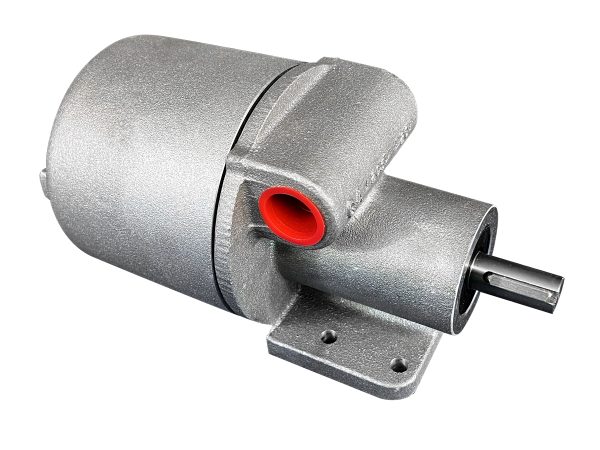

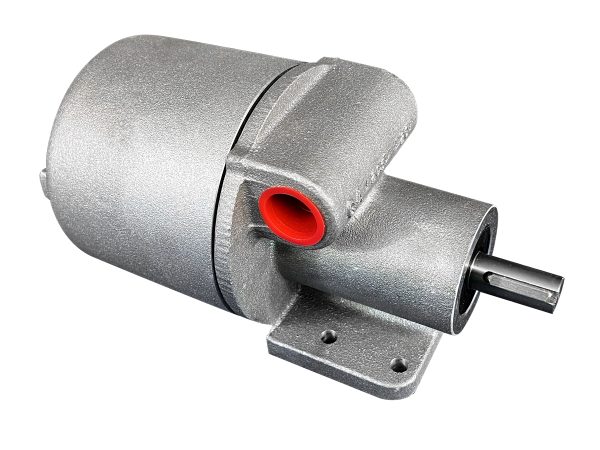

Direct drive indicator

The Model CMS is a direct drive control that indicates when rotating equipment has ceased to turn. The output contacts of the Model CMS can control up to two separate circuits, one for machinery shutdown and one for an alarm.

Benefits

Motion control – compact

The Model BSDC is a compact (reduced-size) version of our heavy duty “traction action” motion control that indicates when a conveyor belt has slowed or quit moving altogether. The unit can be adjusted as an overspeed, underspeed, or zero speed control.

Benefits

Speed indicator

The Model MSD is comprised of two different components, a control unit (digital display) and a speed sensor (pulse generator). The Model MSD-800 control unit is a programmable unit that has two setpoints permitting it to indicate two under-speed points or two over-speed points, or one of each.

Benefits

Rotating shaft indicator

The Model RMS is a non-contact motion control that indicates when a rotating shaft has slowed or quit moving altogether. The unit can be adjusted as an overspeed, under speed, or zero speed control.

Benefits

Level control – tilt probe

The Model CT is comprised of a Control Unit and Tilt Probe senses the presence or absence of material. The new intrinsically safe, cULus Listed Control Unit is enclosed in rugged cast aluminum housing with LED Indicator lights and surface mount printed circuit board.

Benefits

Paddle style level control

The Model CR is a rotating paddle style level control that can indicate the presence (or absence) of dry bulk material within a bin or hopper. The unit can be equipped with either 1, 2, or 3 heavy duty microswitches to control a variety of functions or alarms.

Benefits

Pressure level control switch

The Model DLC is a flush mount, pressure activated, diaphragm style level control and plugged chute detector. The model DLC has 2 dry (unpowered) microswitches that activate when material within the bin or chute presses upon the diaphragm face.